Blister Sealed Packaging

Blister Sealed Packaging Specification

- Product Type

- Sealed Packaging

- Material

- Type

- Thermoformed Packaging

- Style

- Clamshell or Tray Style

- Packing Format

- Blister Sealed

- Hardness

- Rigid

- Filling Capacity

- Custom or as per specification

- Tensile Strength

- High

- Size

- Customizable

- Dimension (L*W*H)

- As per order requirement

- Color

- Transparent / Custom color

Blister Sealed Packaging Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 1 Week

About Blister Sealed Packaging

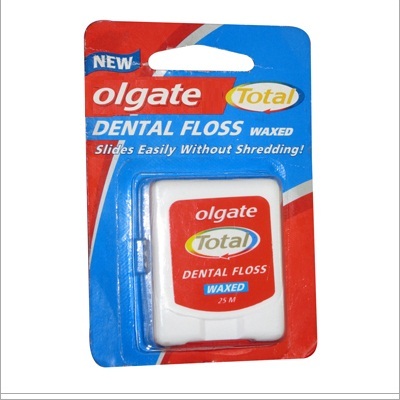

Blister Pack

Being an authentic manufacturer and supplier of Blister Sealed Packing, we have marked a noticeable position in the industry. To satisfy the needs of clients, this material is manufactured using premium quality plastic that is obtained from certified vendors of the market. Prior to dispatch, this material is stringently checked on various parameters to rule out the possibility of any flaw. As per the needs of clients, this Blister Sealed Packing is made available in different dimensions and specifications.

Striking attributes:

-

High tearing strength

-

Long lasting nature

-

Environment-friendly

Customizable and Durable Packaging Solutions

Blister sealed packaging can be tailored to specific dimensions, thickness, and shapes according to order requirements. Its rigid structure and high tensile strength protect your products, while both rectangular and custom shapes are available. Choose from a variety of color and finish options for ultimate product presentation and branding.

Tamper Evident and Moisture Resistant Features

Every blister pack is heat sealed to provide a tamper-evident barrier, ensuring product authenticity and safety. The moisture-resistant properties keep sensitive items such as electronics, pharmaceuticals, and cosmetics secure from external elements, extending shelf life and maintaining quality during distribution.

Sustainable and Brand-Forward Packaging

Depending on material selection, many blister sealed packaging options are recyclable, supporting sustainability goals. With printing options for logos, instructions, and branding, these packages offer excellent product visibility through high transparency and enhance your brands presence on store shelves.

FAQs of Blister Sealed Packaging:

Q: How is blister sealed packaging used for different industries?

A: Blister sealed packaging is widely used to securely contain and display consumer goods, electronic items, pharmaceuticals, and cosmetics. Its tamper-evident and moisture-resistant features help protect products from damage, contamination, or unauthorized access, making it ideal for retail and healthcare applications.Q: What is the process for manufacturing blister sealed packaging?

A: The process involves thermoforming plastic films such as PVC or PET into rigid shapes like trays or clamshells. Products are placed within these forms, then sealed using heat to create a secure, tamper-evident enclosure. Printing and customization options can be added before final shipment.Q: When should I consider choosing custom thickness or size for blister sealed packaging?

A: Custom thickness or size is recommended when you have unique product specifications, require added protection, or need to meet specific retail display requirements. Customized dimensions help ensure a snug fit, enhance shelf presence, and improve product security.Q: Where can I source blister sealed packaging in India?

A: You can source blister sealed packaging through manufacturers, dealers, suppliers, traders, and wholesalers across India. Many providers offer flexible order quantities, customization, and end-to-end support to meet a wide range of industry needs.Q: What are the primary benefits of choosing heat-sealed blister packaging?

A: Heat-sealed blister packaging offers tamper evidence, moisture resistance, and enhanced product safety. It also provides high durability, a glossy or matte aesthetic, and options for clear or custom coloring and printing, supporting both branding and protection goals.Q: How is the packaging environmentally friendly?

A: Many blister sealed packages use recyclable plastic materials, such as PET or select PVC grades, supporting environmental sustainability. Material selection can be tailored to ensure compliance with recycling standards as needed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Slide Blister Packaging Category

Blister Plastic Packaging

Price Range 5.00 - 50.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, PVC / PET / HIPS

Dimension (L*W*H) : As per Requirement

Type : Other, Thermoformed Blister

Product Type : Other, Plastic Packaging

Blister Cosmetic Packaging

Price Range 5.00 - 50.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, PET / PVC / HIPS Plastic

Dimension (L*W*H) : Standard: 160 x 100 x 25 mm (Custom on Request)

Type : Other, Clamshell/Blister

Product Type : Other, Cosmetic Packaging

Blister Packs

Price Range 5.00 - 50.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, PVC, PET, HIPS

Dimension (L*W*H) : As per requirement

Type : Other, Thermoformed Blister Pack

Product Type : Other, Packaging Blister Pack

Blister Packing Box

Price Range 5.00 - 50.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Plastic (PVC/PET)

Dimension (L*W*H) : As per requirement

Type : Other, Blister Packing Box

Product Type : Other, Packaging Box

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry